Carbonated beverage filling production line is composed of four parts: material system, bottle blowing system, mixing and mixing system, filling and packaging system. Production capacity can be reached 2000-24000BPH.

1.This kind of complete set of drink filling machine combines washing,filling and rotary capping functions in one unit,is a fully automatic and high efficiency liquid packing equipment.

2.It is suitable for packing carbonated soft drink ,beverage containing gas. Its performance is as following all parts,for instance, filling valve, which directly contact medium are made of stainless steel or harmless material. So it conforms to the requirements of Food sanitation. Sealing parts are made of heat-proofing rubber from JST company, in order to meet the technique requirements of users to sterilization at high temperature.

3.filling machine ,using programmable controller to realize fully automatic control from bottles entering to finishing packing, Using transducer as speed regulator from JST company, so the user can regulate the machine easily to suit different power requirements, Adopting equal pressure filling principle and current spring valves in order to assure beverage quality, Using advanced magnetic coupler to regulate cap-screwing torque, in order to assure capping quality

Production capacity can be reached 2000-24000BPH.

| Model | DCGF14-12-5 | DCGF18-18-6 | DCGF24-24-8 | DCGF32-32-10 | DCGF40-40-12 | DCGF50-50-15 |

| Output | 2000 | 5000 | 7000 | 10000 | 15000 | 20000 |

| Power | 3 | 4 | 5.5 | 7.5 | 11 | 15 |

| Weight | 2200 | 3000 | 4500 | 6000 | 9000 | 15000 |

1.Compact structure, saving workshop space

2.All parts in contact with materials are made of high-quality stainless steel

3.The machine adopts imported electrical components with reliable quality

4.High filling speed and accurate liquid level control

5.PLC control, high degree of automation

Using high-precision carbonated filling nozzle, there will be no uneven filling liquid level.Ensure the quality of the final product. Optimize the overall machine structure, purchase high-quality stainless steel and high-quality electrical components, improve the productionefficiency of the machine and reduce the failure rate.

Water quality guarantee is to ensure product quality, through the above process of water treatment equipment for raw water after treatment can achieve China’s national drink mineral water standard, the whole process of water treatment for the customer water through the booster pump pumping into the stainless steel material of the original water tank, the original water tank water again this after booster pump to enhance the water pressure into the quartz sand filter, quartz sand filter, the main effect of sodium ion exchanger is effective to remove the impurity in the raw water and sediments, clear water, after the end of this process through a pipe (can is stainless steel, PVC pipe) into the activated carbon filter, the process is the key, Activated carbon can effectively remove the peculiar smell in the water. The precision filter at the back and the hollow fiber filter are the principles of membrane filtration. In this process, the non-beneficial components in the water can be effectively removed. The water treatment line is made of 304 stainless steel, and the electrical appliances, pumps and motors are all provided by domestic and foreign quality suppliers with high cost performance.

The CSD mixing system can tailor the exclusive production process according to the unique characteristics of various beverages. We will carefully design the preparation process according to the beverage formula, and build a complete CSD beverage production system. The system covers a variety of key equipment such as sugar melting tank, mixing tank, heating and cooling tank, sterilizer and so on. No matter what kind of unique formula you have, we can customize the exclusive machine for you, which is mainly used in the pre-treatment process of beverage production. The system adopts welding technology and high-precision polishing technology, and is made of high-quality stainless steel 304/316 material. It has a scientific and reasonable process design and realizes automatic control to ensure that the production process is efficient, stable and of excellent quality.

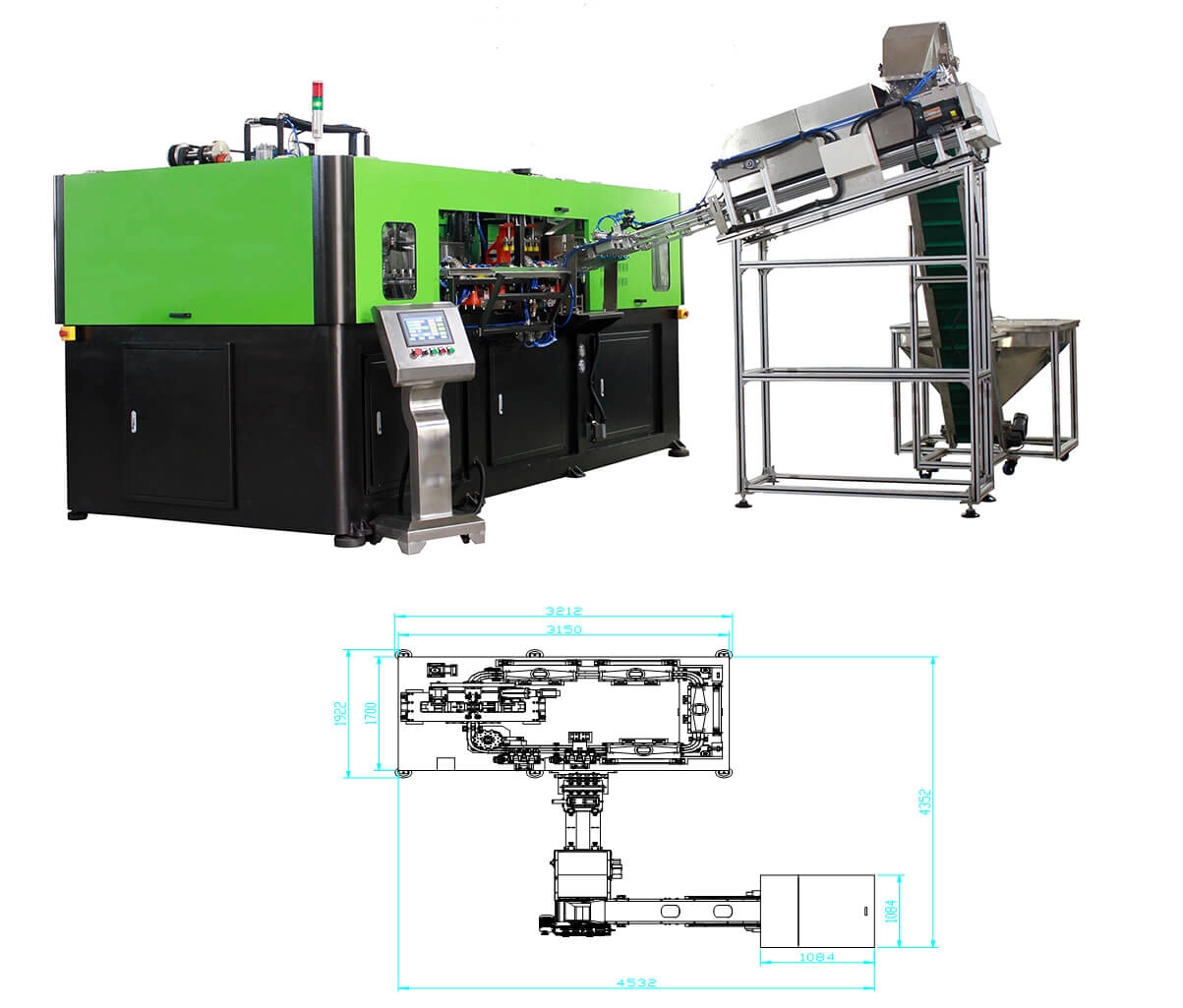

Linear blow molding machine is a high speed automatic PET blower designed and developed with the most advanced bottle blowing technology at present, the advantages of which can be described as speedy, stable, simple, general purposed and environmental safe. It is mainly applicable in blow molding cold filling and mesothermal filling PET containers for drinking water, beverage, food, daily chemical products, etc. The machine yields abundantly with high efficiency. The capacity of each cavity has been increased to 1750~1500bph from original 1000bph when the bottle size is equal to or less than 0.6L respectively, which can meet the high-end customer’s requirements. Equipped with preform auto loading system, the machine works fully automatically with consistent performance and high speed, without any operator’s interference during the whole processes. Accordingly, chance of contamination can be reduced manifestly, which assures the quality of products.

3 in 1 Carbonated Drink Filling Machine:

1.Compact structure, saving workshop space

2.All parts in contact with materials are made of high-quality stainless steel

3.The machine adopts imported electrical components with reliable quality

4.High filling speed and accurate liquid level control

5.PLC control, high degree of automation

Belt conveyor used for complete plant bottle and cans transferring. can be customzied accroding to clients’ detailed request and plant design. We provide different types of conveyors, corners, several rolls, rollling conveyors, etc.

OPP label, as a plastic film, is known for its high transparency, strong durability and good printability. It has excellent moisture resistance, chemical corrosion resistance, and good dimensional stability, so it can be widely used in various product and packaging scenarios. The OPP labeling machine has various functions, and can label various products and containers such as bottles, cans, boxes, etc. The equipment is suitable for food and beverage, pharmaceuticals, health care products, household products and other industries, providing efficient and accurate labeling solutions for product packaging in various industries, greatly improving the aesthetics and standardization of product packaging.

1.Classic shape, beautiful, novel structure, unique, easy operation and maintenance. The use of pneumatic expansion support film roll, electronic sensor film delivery, sending film stable, fast and convenient for membrane.

2.Unique threat shaking bottle can make the product smooth separation, avoiding the phenomenon of squeeze bottle.

3.Feeding conveyor and host length is 1.6 meters longer than other company, is conducive to the sorting of the bottles, effectively increasing the number of membrane rods to reduce the transmission line speed and increase the tolerance of equipment performance.

4.Shrink chamber using a unique circular air supply technology to achieve multi-directional air flow control technology, adjustable wind speed, adjustable outlet position, greatly improving the shrinking effect.

5.Shrinkage chamber using the newly developed open structure outside to facilitate maintenance; thick insulation layer, energy-saving effect, high temperature control accuracy.

China DATONG specialized in water&beverage producing and packing solutions since 2002. Modern factory of 6000 square meters.

Over 40 countries' customers are using DATONG machines. We cam provide 24 months long warranty and the whole production line, factory design, design bottle, provide a layout diagram, provide auxiliary materials supply agent information, machine installation and debugging, staff training and soon.

To know more find out from our website www.datong-machine.com