DATONG juice production line is mainly applicable to tea, juice, including milk drinks, functional drinks, etc.

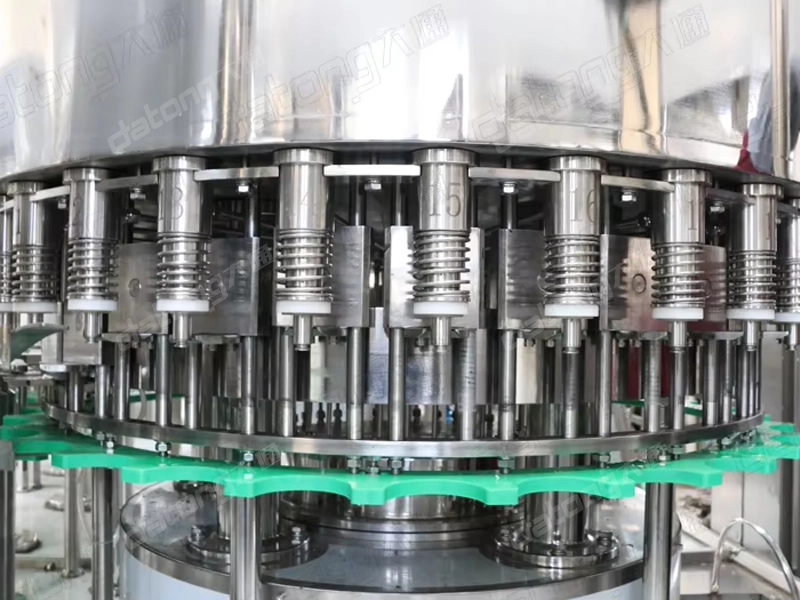

The standard type of filling machine is “three in one”, which is integrated with washing filling and capping. For special production conditions, it can also add a sterilizing bottle, that is, “four in one”. The production capacity can reach 2500-26000 b/h, with a total power of 3-20 kW and a total weight of 2200-18000 kg. It is suitable for round or square bottles. The above technical parameters are for reference only. We can adjust them according to your requirements. The good hot juice filling machine is an option you can’t miss.

Production capacity can be reached 2500-30000BPH.

| Model | RCGF | RCGF | RCGF | RCGF | RCGF | RCGF | RCGF | RCGF |

| Model | 14-12-5 | 16-16-6 | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-12 | 50-50-15 | 60-60-15 |

| Production capacity(b/h) | 2500 | 4000 | 6000 | 8000 | 13000 | 18000 | 22000 | 26000 |

| Suitable bottle | circular or square | |||||||

| shape | ||||||||

| Bottle diameter(mm) | Φ50-95 | |||||||

| Bottle height(mm) | 150-310 | |||||||

| Washing medium | aseptic water | |||||||

| Tatal power(kw) | 3 | 3.5 | 4 | 5.5 | 7.5 | 11 | 15 | 20 |

| Weight(kg) | 2200 | 2800 | 3000 | 4500 | 6000 | 9000 | 15000 | 18000 |

Automatic juice filling equipment is a complete set of production equipment containing washing, filling, and capping (3 in 1). For special juice filling, we also have a sterilization (4 in 1) filling machine, because fresh alimentation products need a special filling method to keep it fresh and preserved. This automatic juice-filling machine is mainly used for filling juice drinks, pure water, and other non-vapor drinks. Datong Machinery is an industry-leading manufacturer of juice-filling machines in China. Our Juice liquid filling machines are designed to meet the changing needs of the industry and your customers. We manufacture the ideal machinery for your juice bottle packaging line with high production capacity. Our machines are ideal for bottling fresh or pasteurized fruit juice since they are made with high-quality materials. Even pulpy juices or liquids that need to be heated can be bottled with our machine. You are welcome to contact us to inquire more about the customized filling machine. We will be more than happy to assist you.

The juice making system is ingenious, which can accurately understand the characteristics of different types of juice, and tailor the exclusive production process accordingly. On the basis of the juice beverage formula, a complete juice preparation process is carefully planned to create a one-stop complete system for the production of juice beverages. No matter what kind of unique formula you hold, we can rely on professional strength to customize suitable machines for you to meet your personalized production needs in an all-round way.

CIP cleaning system is a cleaning system that can clean the production line without dismantling the equipment. It circulates cleaning liquid through airtight pipes, and uses chemical energy, thermal energy and mechanical energy to remove dirt on the inner surface of the equipment. It is widely used in food and beverage production enterprises with a high degree of mechanization such as beverages, dairy products, fruit juices, jams, and alcohols.

Linear blow molding machine is a high speed automatic PET blower designed and developed with the most advanced bottle blowing technology at present, the advantages of which can be described as speedy, stable, simple, general purposed and environmental safe. It is mainly applicable in blow molding cold filling and mesothermal filling PET containers for drinking water, beverage, food, daily chemical products, etc. The machine yields abundantly with high efficiency. The capacity of each cavity has been increased to 1750~1500bph from original 1000bph when the bottle size is equal to or less than 0.6L respectively, which can meet the high-end customer’s requirements. Equipped with preform auto loading system, the machine works fully automatically with consistent performance and high speed, without any operator’s interference during the whole processes. Accordingly, chance of contamination can be reduced manifestly, which assures the quality of products.

RCGF series is designed and manufactured based on the latest technology from Germany and Italy, for the demand of technical requirement of beverage production, as juice.The filling mono-bloc works as follows: Bottles are fed from conveyor chain into the filling machine mono-bloc via star wheel. Bottle clamp installed on the rotary wheel of the rinse will grip bottle mouth and make a 180° turn along a guide track to face the bottle mouth downward. In designated section of the rinse, rinsing water will jet out from special nozzles to flush bottle inside wall. After rinsing and dripping, bottles gripped by bottle clamp will make another 180° turn along a guide track to resume bottle mouth facing up position. Clean bottles are discharged out of the rinse by a star wheel to feed the filler. After entering the filler, bottles are retained by neck supporting carrier plates, which are actuated by bottle carrier mechanism to raise them to engage with filling valves. Filling valves are opened by bottle presence signals. After finishing filling, valves are closed by valve closing mechanism to further stop venting to complete the filling process. Bottle carrier mechanism is lowered by a cam to disengage filled bottles with filling valves. Then bottles are transferred into the capper by a neck handling star wheel. Anti-rotation blades on capping heads will seize the bottleneck to prevent it from rotation and hold it in a upright position. The twist-on capping head will make revolving and rotating movement along with the machine to finish the complete capping process of cap picking, placing, twisting, and disengaging under the control of a cam. A discharge star wheel discharges finished bottles onto discharge conveyor belt to be conveyed out of the filling mono-bloc.

Shrink sleeve labeling machine professionally produced by Reliable Machinery has advantages of high speed, good quality, high efficiency, better price performance and simple operation. The labeling machine is used in drinks, beverages, dairy products, cosmetics, condiments, drugs, health products, chemicals, candy toys, sewing thread, tape, electronic products and other industries. It is also suitable for round,square,flat,cup,conical,special-shaped bottles.

1.Classic shape, beautiful, novel structure, unique, easy operation and maintenance. The use of pneumatic expansion support film roll, electronic sensor film delivery, sending film stable, fast and convenient for membrane.

2.Unique threat shaking bottle can make the product smooth separation, avoiding the phenomenon of squeeze bottle.

3.Feeding conveyor and host length is 1.6 meters longer than other company, is conducive to the sorting of the bottles, effectively increasing the number of membrane rods to reduce the transmission line speed and increase the tolerance of equipment performance.

4.Shrink chamber using a unique circular air supply technology to achieve multi-directional air flow control technology, adjustable wind speed, adjustable outlet position, greatly improving the shrinking effect.

5.Shrinkage chamber using the newly developed open structure outside to facilitate maintenance; thick insulation layer, energy-saving effect, high temperature control accuracy.

China DATONG specialized in water&beverage producing and packing solutions since 2002. Modern factory of 6000 square meters.

Over 40 countries' customers are using DATONG machines. We cam provide 24 months long warranty and the whole production line, factory design, design bottle, provide a layout diagram, provide auxiliary materials supply agent information, machine installation and debugging, staff training and soon.

To know more find out from our website www.datong-machine.com