How to choose machines and build up a water factory?

Used for pure water, mineral water and other bottled water,water for food and beverage production.

It is mainly composed of the following equipments: pre-treatment system (water tank,multi-medium filter, active carbon filter, ionexchanger, millipore filter), membrane separation system (ultra filter, nanometer filter, RO system), electrodialysis device, sterilization system (UV device, ozone device), product water tank and so on.

Drinking water can be prepared by electrodialysis method, ion exchanger method, reverse osmosis method, distillation method and other appropriate processing methods, sealed in a container, without any additives, colorless and transparent, and can be directly consumed.

Raw water centrifugal pump → Sand filter → Carbon filter → Fine filter → First stage reverse osmosis → Secondary reverse osmosis → Ozone sterilization

Drinking water plants obtain potable water through water treatment processes, in which reverse osmosis technology is an important part, which can effectively remove charged ions, inorganic substances, colloidal particles, bacteria and organic substances in water.

Production capacity can be reached 2000-24000BPH.

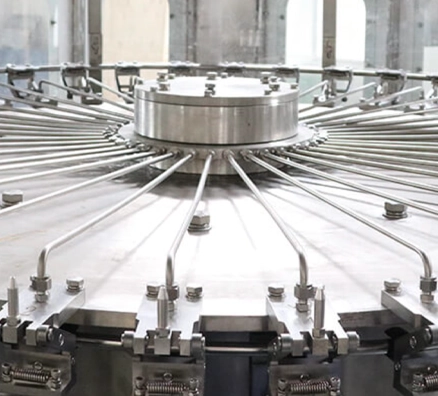

The rotary wheel is a fully SUS304 stainless steel welded structure. The machine applies unique overturning bottle clamp, which is an innovation of our company. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp. Made of SS304 stainless steel, this bottle clamp is hygienic and durable. The high efficiency atomizing spray nozzle installed on bottle clamp incorporating technology from Spaying Systems Co. Ltd., is capable of cleaning any part of bottle inner wall, and also saves rinsing water. The rinse is driven by driving system positioned inside machine frame via gear transmission.

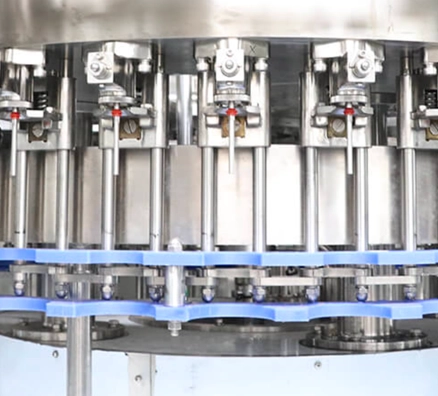

The filler is designed and manufactured with application of Italy technology, providing hardware guarantee for securing product quality and reducing loss. Rotary wheel are fully made of stainless steel SS304. Filling valves are designed and manufactured with German technology, made of SS304, featuring high filling accuracy and high filling speed. Bottles are raised and lowered by cam controlled lifting cylinder. Valve opening mechanism is actuated by air cylinder. Hydraulic pump is float-ball controlled.

The capper is most precise part in 3 in 1 filling machine, because the quality of machine is important to running credibility and product quality. The sealing machine in our company has strongpoint as follows: The cover track has the device to prevent the reversal cover from passing and pick out the reversal cover. Meanwhile the photoelectric switch can stop the machine automatically when there is no cover on the track, by which it can avoid bottle without cover effectively. It also has the bottle check-up switch. Together with cylinder on the joint of the cover track and cover lift, they can control the cover flow and stop it in case no bottle to reduce the quantity of cover. Highly effective acentric way for cap sorting to reduce the abrasion. It has the check-up device to control the cover lift.

China DATONG specialized in water&beverage producing and packing solutions since 2002. Modern factory of 6000 square meters.

Over 40 countries' customers are using DATONG machines. We cam provide 24 months long warranty and the whole production line, factory design, design bottle, provide a layout diagram, provide auxiliary materials supply agent information, machine installation and debugging, staff training and soon.

To know more find out from our website www.datong-machine.com