1.Compact structure, saving workshop space

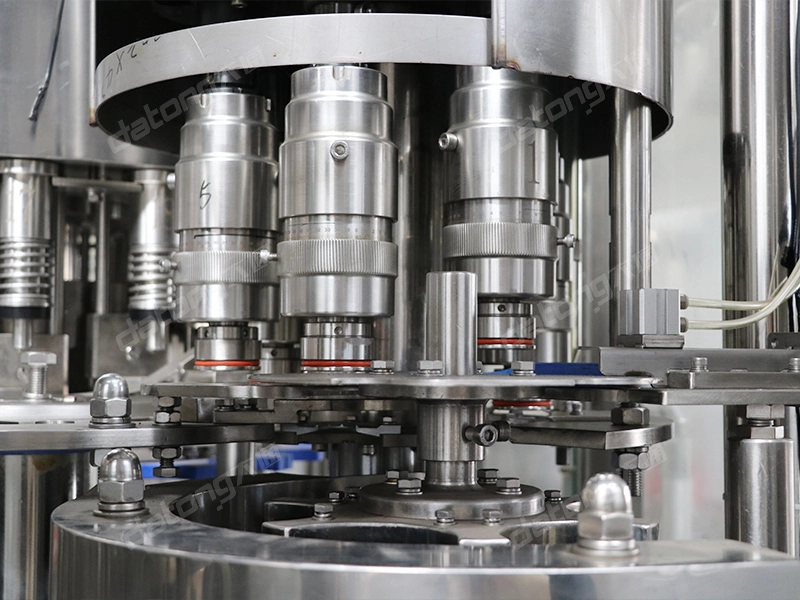

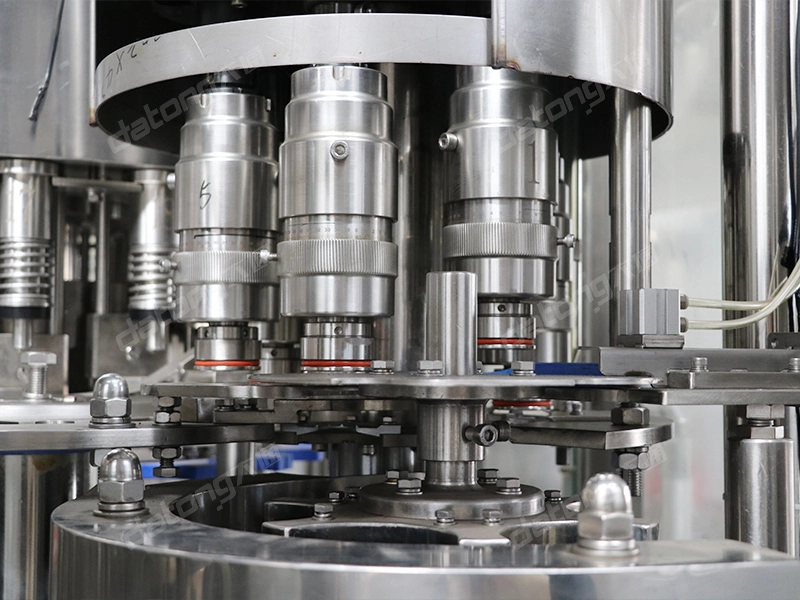

2.All parts in contact with materials are made of high-quality stainless steel

3.The machine adopts imported electrical components with reliable quality

4.High filling speed and accurate liquid level control

5.PLC control, high degree of automation

1. The mineral water filling machine adpots advanced human-machine interface control. High quality international name brand key components

2. Suspension bottle neck catcher structure allows the machine change the bottle type easily. By changing the valves, it also can be used as hot filling machine

3. Spring type rinsing catcher can wash both inside and outside of the bottle

4. High accuracy pressure water filling mechanism, ensure the height and quatity of the water filling

5. Magnetic powered cap device ensures tightness and prevents damage of the caps

6. Quiet, rotary cap unscrambler will not damage caps. Photoelectric sensor detect missing caps thus eliminating uncapped bottle spillage

7. Built-in safeguard mechanism ensures the safety of operator and machine.

8. High efficient air clean filter system ensures high sanitary requirements

9. Low overall machine noise

10. Self-lubricating system imported from America provides continuous smooth operation

|

Mode

|

CGF14-12-5

|

CGF16-16-6

|

CGF18-18-6

|

CGF24-24-8

|

CGF32-32-10

|

CGF40-40-12

|

CGF50-50-15

|

CGF60-60-15

|

|

Production capacity(B/H)

|

2000-3500

|

3500-5000

|

5000-7000

|

7000-12000

|

12000-15000

|

15000-20000

|

20000-24000

|

24000-30000

|

|

Suitable bottle shape

|

Circular or Square

|

|||||||

|

Bottle diameter(mm)

|

Φ50-Φ95

|

|||||||

|

Bottle height(mm)

|

150-310

|

|||||||

|

Washing medium

|

Aseptic Water

|

|||||||

|

Total power (kw)

|

2

|

3.5

|

4

|

5.5

|

7.5

|

11

|

15

|

20

|

|

Weight (kg)

|

2200

|

2800

|

3500

|

4500

|

6000

|

9000

|

15000

|

18000

|

|

Overall dimensions(mm)

|

2050*1550*2200

|

2400*1750*2200

|

2550*1850*2200

|

3000*2150*2200

|

4200*2700*2400

|

4700*3200*2400

|

6500*3350*2400

|

7200*3650*2600

|