| Volume (Gallon) | 3&5 |

|---|---|

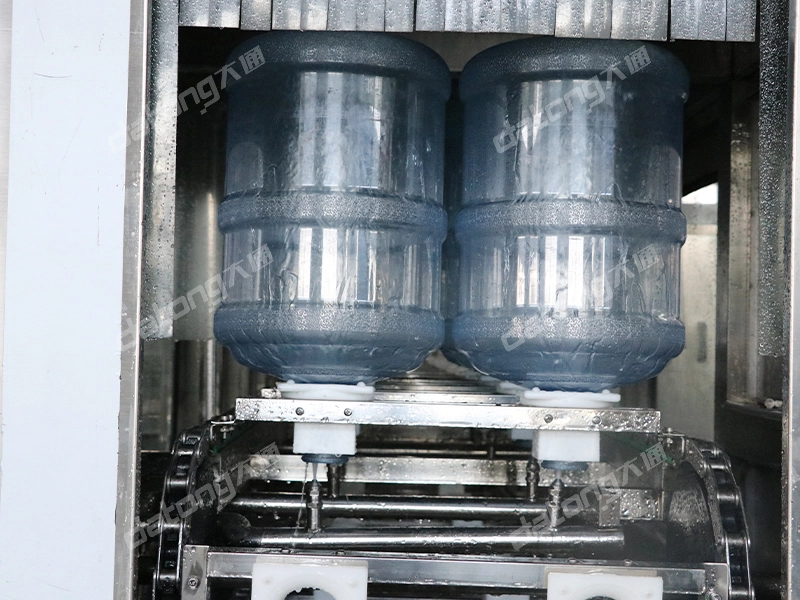

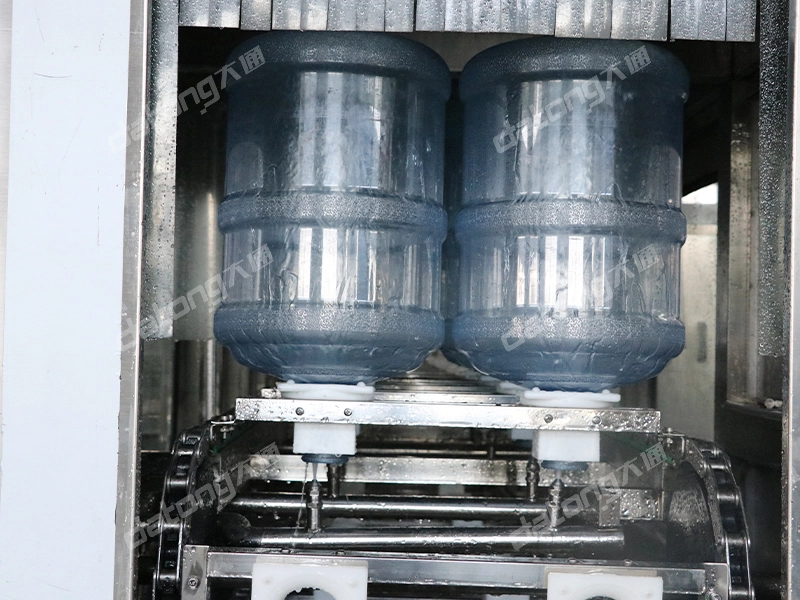

| Barrel size (mm) | Ф270*490 |

| Power | 4kw |

| Capacity of production | 300BPH-1200BPH |

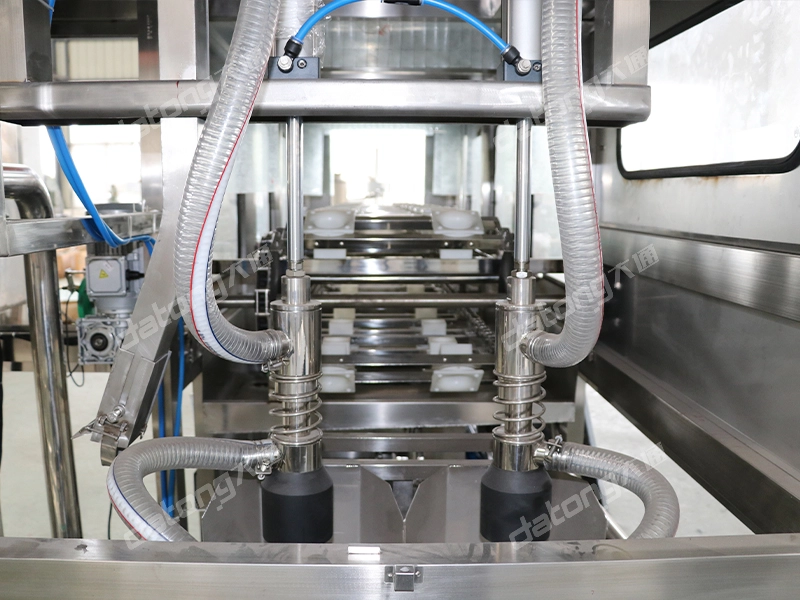

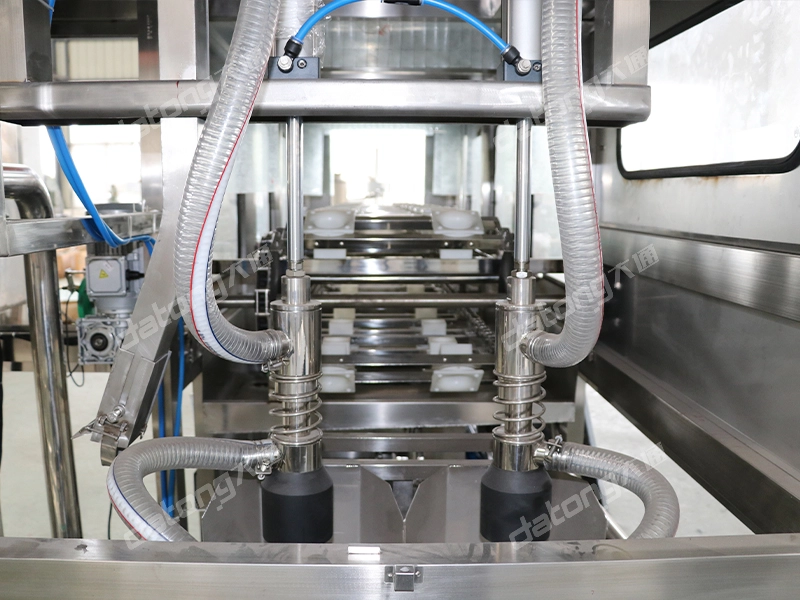

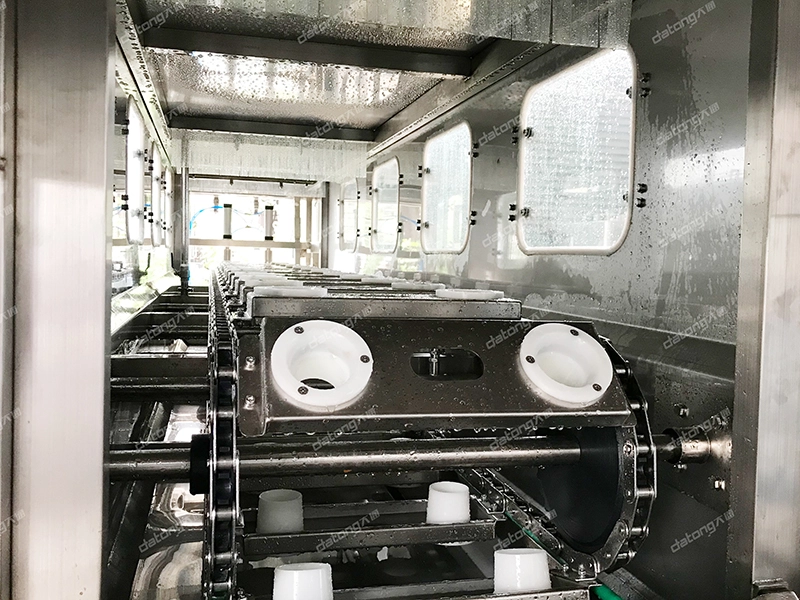

5 gallon filling machine is composed of a frame, a water tank, a pipe, a water pump, a cylinder, a transmission, an electrical appliance, etc. It can complete empty barrel flushing, filling, capping and other actions. Through multiple flushing procedures, quantitative filling, automatic capping with a cap, and computer control of all actions of the whole machine, it can achieve stable flushing effect, accurate filling capacity, and sealed capping effect.

1. Fully automated operation

This filling machine integrates cleaning, filling and capping. The automatic cleaning system can thoroughly rinse the inside and outside of the bottle to ensure that the hygiene standards are met before filling. The capping device is accurate and reliable, effectively ensuring product quality.

2. Efficient production capacity

The equipment can produce up to 1,200 bottles per hour, suitable for all types of operations from small to large. Its high-speed, fully automatic process can stabilize production, reduce downtime, and easily integrate into existing 3-5 gallon filling lines to further improve efficiency.

3. Flexible customization

We are well aware of the uniqueness of each production line, so we provide customized options for bottle size, capacity and additional functions (such as ultraviolet sterilization) to meet your personalized production needs.

4. Energy-saving optimization

The filling machine uses a low-energy pump and an optimized flushing cycle to reduce power consumption, combining economic and environmental advantages.

| Model | YDGF12-4 | YDGF18-4 | YDGF20-4 | YDGF30-6 |

| Capacity | 3000CPH | 6000CPH | 10000CPH | 15000CPH |

| Can diameter | φ52.5-99mm | |||

| Can Height | 39-160mm | |||

| Power | 3.5kw | 5.5kw | 6.75kw | 7.5kw |

| Weight | 2500kg | 3500kg | 4000kg | 5000kg |

| Dimension | 2100*1500*1900mm | 2450*1750*2200mm | 2650*2200*2200mm | 3050*2250*2200mm |