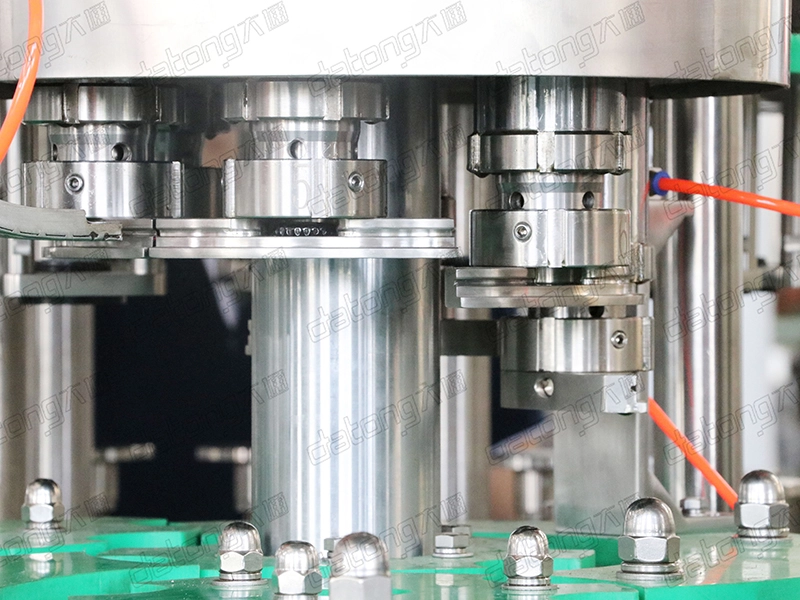

The filling machine has the characteristics of high automation. From bottle washing, filling, and capping of glass bottles, every link can operate accurately under the control of the automation system. The sensor monitors the position and status of the glass bottle in real time to ensure the accuracy of the filling process and the defective rate. The key components of the filling machine are made of high-quality stainless steel, which is not only durable, but also has good corrosion resistance. It can withstand the acid attack of carbonated drinks, prolong the service life of the equipment, and maintain costs.

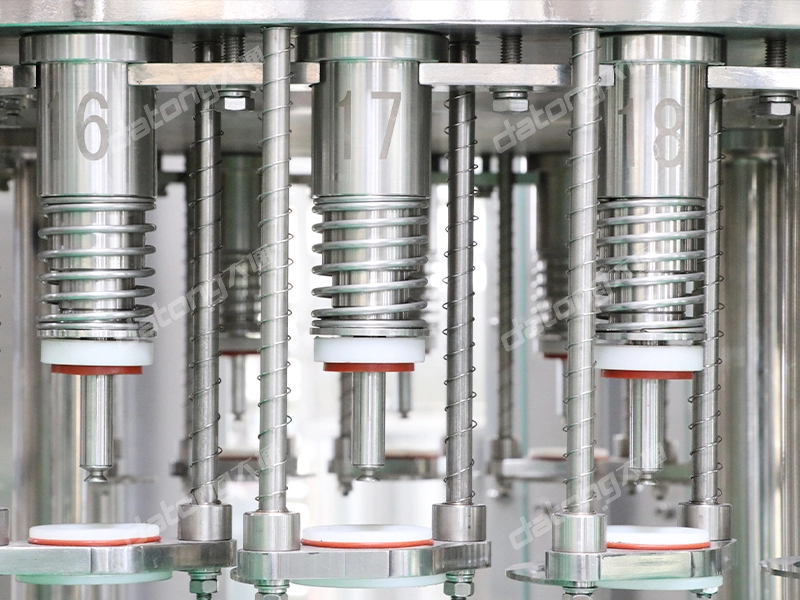

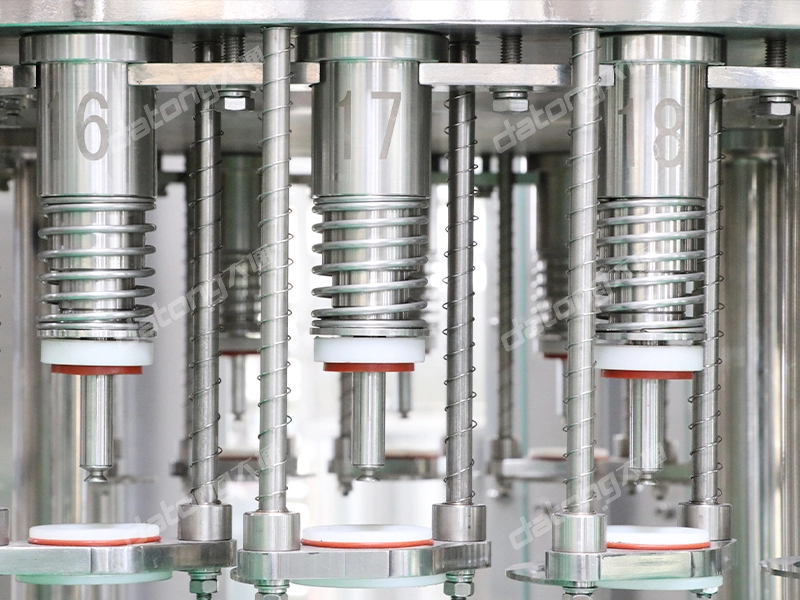

1. Technical professional: The use of isobaric filling, maintain the balance of pressure in the bottle, filling fast and stable, but also reduce the escape of bubbles, to ensure the taste of drinks.

2. High level of automation: from bottle delivery to cap full automation, sensor real-time monitoring, reduce the rate of defective.

3. Material selection and durability: key components with high-quality stainless steel, corrosion resistance, prolong equipment life, reduce maintenance costs.

4. High capacity adaptation: reasonable design, optimization process, fast speed, high precision, to meet the production of different scale enterprises.

5. Easy to operate: user-friendly interface, you can start to operate after training.

| Model | RCGF14-12-5 | RCGF16-16-6 | RCGF18-18-6 | RCGF24-24-8 | RCGF32-32-10 | RCGF40-40-12 | RCGF50-50-15 | RCGF60-60-15 |

| Production capacity(b/h) | 2500 | 4000 | 6000 | 8000 | 13000 | 18000 | 22000 | 26000 |

| Suitable bottle shape | circular or square | |||||||

| Bottle diameter(mm) | Φ50-Φ95 | |||||||

| Bottle height(mm) | 150-310 | |||||||

| Washing medium | aseptic water | |||||||

| Total power(kw) | 3 | 3.5 | 4 | 5.5 | 7.5 | 11 | 15 | 20 |

| Weight(kg) | 2200 | 2800 | 3000 | 4500 | 6000 | 9000 | 15000 | 18000 |

| Overall dimensions(mm) | 2050*1550*2200 | 2400*1750*2200 | 2550*1850*2200 | 3000*2150*2200 | 4200*2700*2400 | 4700*3200*2400 | 6500*3350*2400 | 7200*3650*2600 |