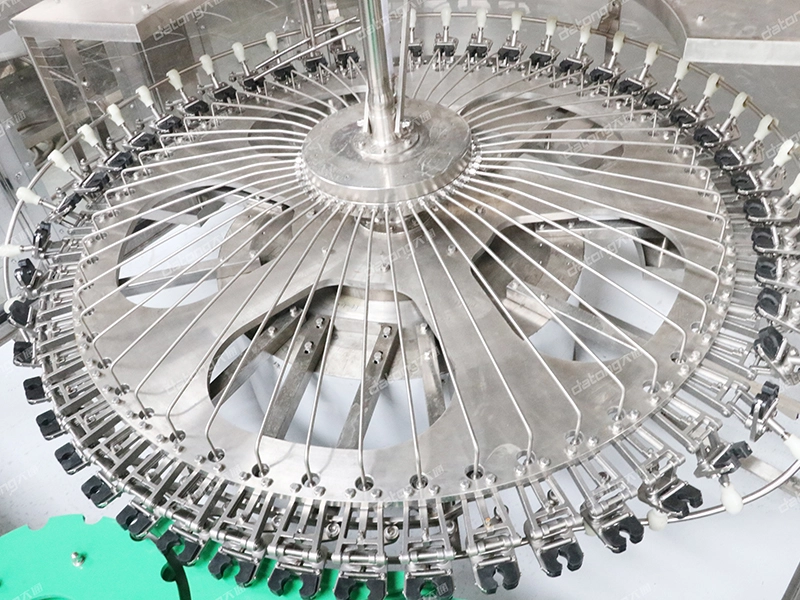

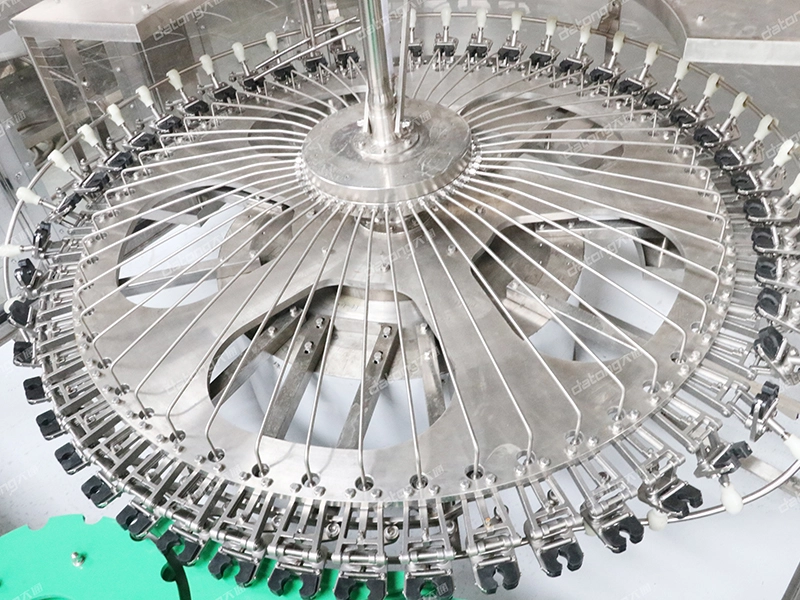

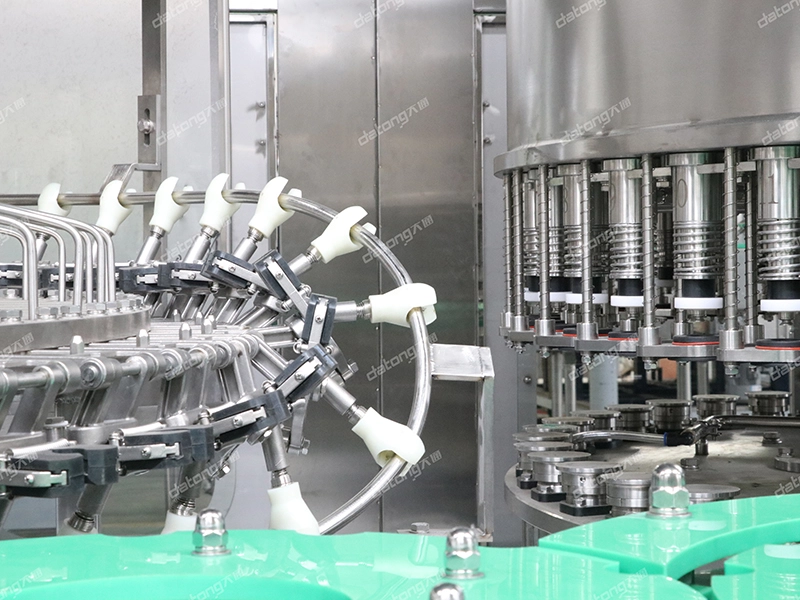

1. The suspended bottleneck clamping design ensures that the entire production line is more stable during the working process and avoids failures caused by different bottle thicknesses or heights. The design also greatly reduces the number of interchangeable parts required, making it more convenient to replace different types of bottles during cleaning, filling and capping.

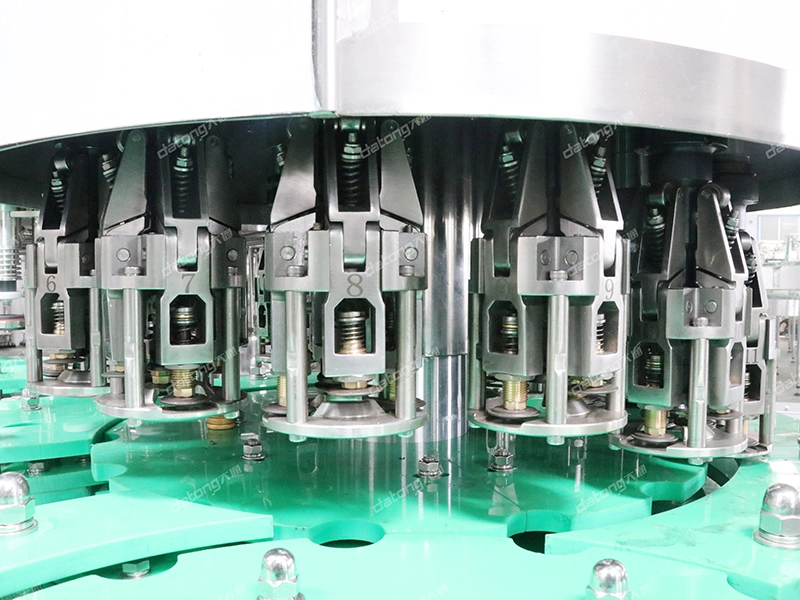

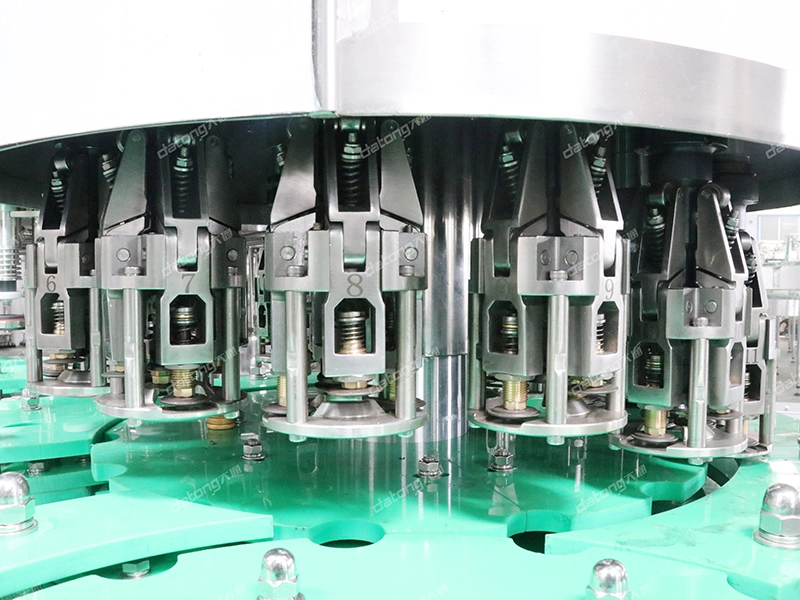

2. The machine adopts advanced gravity filling technology to ensure fast filling and high precision of liquid level control.

3. The bottle capping adopts magnetic torque. The constant capping force can be adjusted steplessly, so the bottle will not be damaged.

4. A horizontal capping sorting device is used to avoid damage to the bottle cap. No cap, no capping; no cap, the feeding system runs automatically.

5. The machine adopts a human-machine interface touch screen and a PLC control system. The liquid level in the tank is automatically controlled. No bottle, no filling, no capping.

6. All parts in contact with water are made of 304 stainless steel.

7. All major component manufacturers are world-renowned manufacturers.

| Model | RCGF14-12-5 | RCGF16-16-6 | RCGF18-18-6 | RCGF24-24-8 | RCGF32-32-10 | RCGF40-40-12 | RCGF50-50-15 | RCGF60-60-15 |

| Production capacity(b/h) | 2500 | 4000 | 6000 | 8000 | 13000 | 18000 | 22000 | 26000 |

| Suitable bottle shape | circular or square | |||||||

| Bottle diameter(mm) | Φ50-Φ95 | |||||||

| Bottle height(mm) | 150-310 | |||||||

| Washing medium | aseptic water | |||||||

| Total power(kw) | 3 | 3.5 | 4 | 5.5 | 7.5 | 11 | 15 | 20 |

| Weight(kg) | 2200 | 2800 | 3000 | 4500 | 6000 | 9000 | 15000 | 18000 |

| Overall dimensions(mm) | 2050*1550*2200 | 2400*1750*2200 | 2550*1850*2200 | 3000*2150*2200 | 4200*2700*2400 | 4700*3200*2400 | 6500*3350*2400 | 7200*3650*2600 |